Collaborate with DeWalt to tailor a precision drilling solution for the construction industry. Boris robot system is an end-to-end suite of technologies streamlines the entire drilling workflow, from map parsing to decision-making for hole placement.

Project by youtube.com/watch?v=k1u5or_M4JQ

TARGET USERS

Construction contractors and on-site operators.

BUSINESS GOAL

To develop a new drilling system on current robot fleet server and client portal.

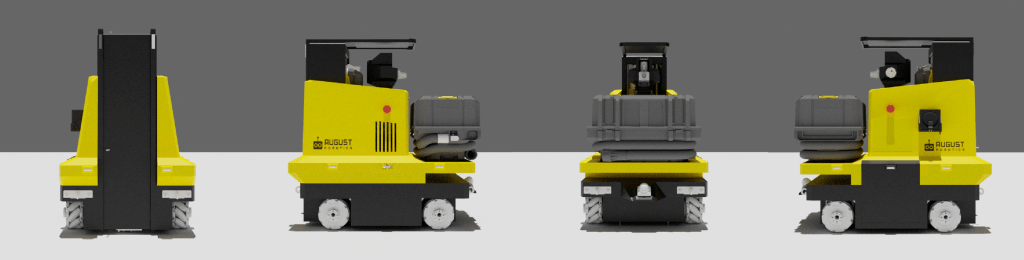

INDUSTRIAL DESIGN

Following the Lionel robot design, I assist on the outer shell design base on the new development of internal structure.

In the initial stage, I tried to align the Lionel robot into a regular shape. Another thing to consider is combining the beacon shelter with the handle at the back.

At last stage, the colour is align with DeWalt brand guideline. Segment the main body into two sections to facilitate an easier disassembly and maintenance of the drill bit housing. Additionally, attach a cover directly onto the beacon to shield the light source.

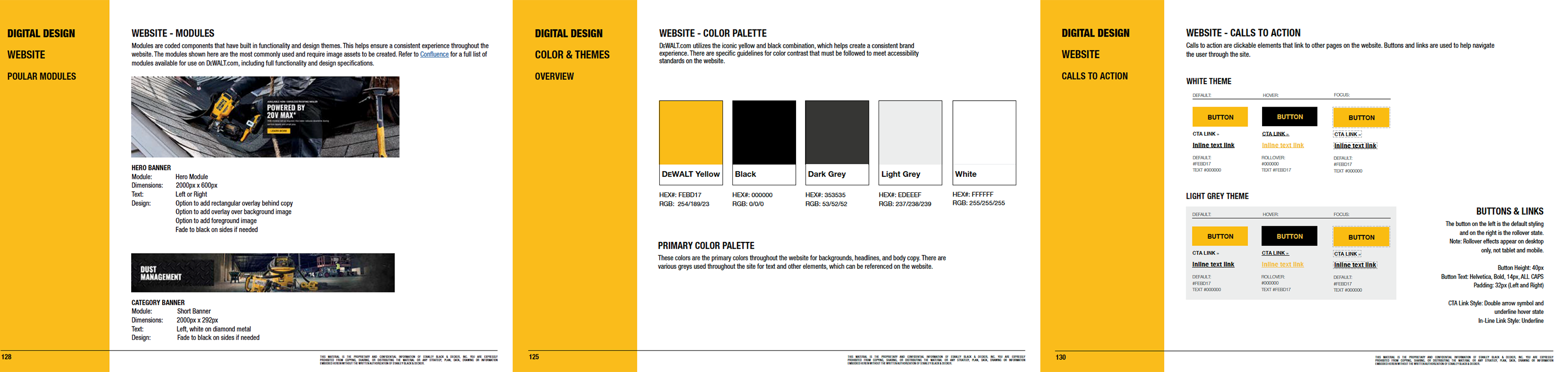

USER INTERFACE REVAMP

Reference to the DeWalt’s brand book, I adopt their design assets and into the Lionel system, ensuring brand consistency across the platform.

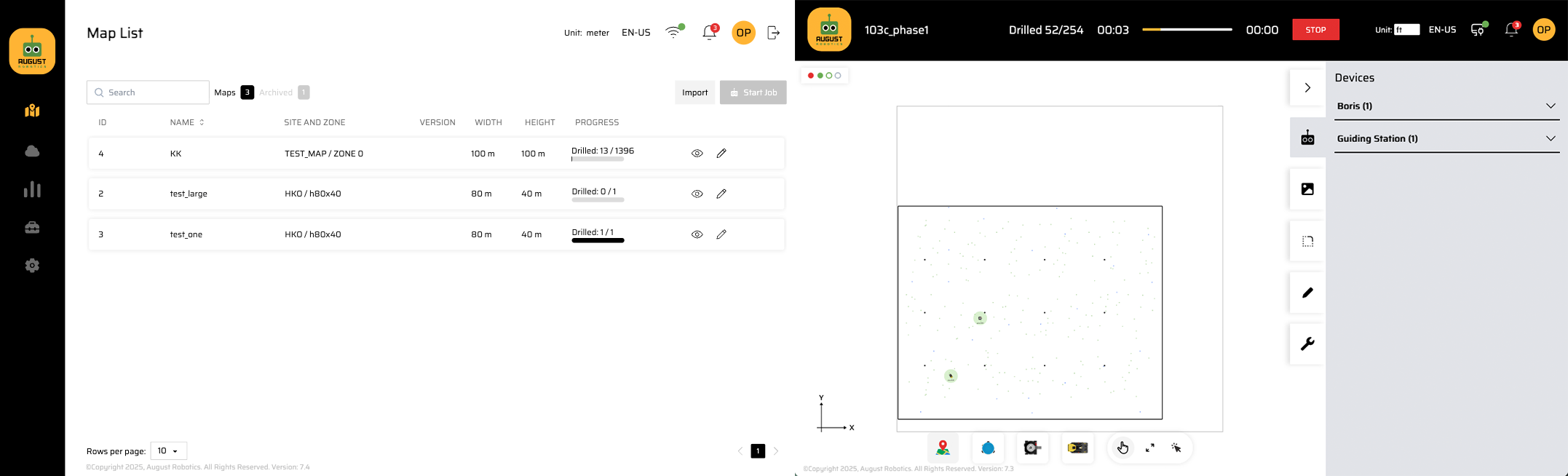

The primary enhancement involves repositioning the navigation bar from the left side to the top during the run job. The margins are also cut off to optimise the use of screen area.

The Control Panel has been redesigned with an expandable and collapsible UI.

The next phase involves a filter and dropdown menu to categorise the Boris and Lionel robots, allowing for simultaneous monitoring of the drilling and marking status.

The Edit Control Panel displayed in both the Map Table and Run Job interface. I revised the card design to make them adaptable for use on two contrasting background colours.

COMPETITOR ANALYSIS

Another key distinction lies in the data metrics displayed on the dashboard. We conducted a comparative analysis at the company, job, and project levels.

USABILITY TESTING

Our team continued to test the drilling process with different hole size and depth calibration.

PROPOSED SOLUTION

Create a new calibration user experience to address the complexities of robot setup and accuracy of drilling process.

MULTIPLE ACCESS POINTS

- Auto and Manual – Boris and Guiding Station Calibration

- Drillbit Validation – Drillbit Depth and Diameter

- Map legend – Mark View and Edit Practice

- Settings – Dust and Rebar Control

Here’s the High-Fidelity Prototype of the Fleet Server and User Portal. Our teams continued to do calibration on drilling results.

Fleet Server: https://www.figma.com/BorisRobotSystem/FleetServer

User Portal: https://www.figma.com/BorisRobotSystem/UserPortal